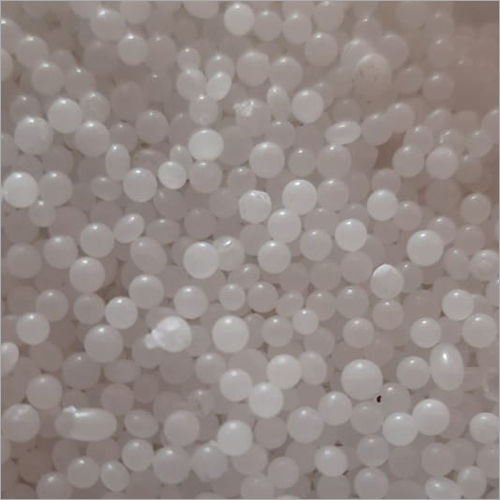

Avail Superior Quality of Natural Expandable Polystyrene Beads & White Expandable Polystyrene Beads From Us.

New Arraival Products

RATTAN STYRENICS PRIVATE LIMITED

GST : 06AALCR1520Q1Z2

Avail Superior Quality of Natural Expandable Polystyrene Beads & White Expandable Polystyrene Beads From Us.

Avail Superior Quality of Natural Expandable Polystyrene Beads & White Expandable Polystyrene Beads From Us.

Our business is guided by most experience professionals having incredibly wide exposure in development of business. Using top quality raw material, contemporary machines and innovative technology, together with an experienced workforce, the manufacturing process at Rattan Styrenics Pvt. Ltd. has been specially designed to ensure consistent standards of quality every time. Recognized in market for products symbolizing reliability, robustness, durability, high-end finishing and premium packaging, our EPS products undergo rigorous checks before final delivery.

We have more than a decade experience in manufacturing of EPS through our subsidiary companies with state of art manufacturer in the production of absolute quality EPS and distribution. Technological proficiency, innovation in product development, maintaining the quality and varieties of the product and providing outstanding customer services strengthen our objective of establishing our strategic planning and our routine plan of action. However, Rattan Styrenics Pvt. Ltd. Was incorporated in 2021 to run the business.

Rattan Styrenics Pvt. Ltd. within a short span of time since its commencement have gained overwhelming status as the leading manufacturers and suppliers of EPS (Expandable Polystyrene). We have incorporated latest technologies in EPS resin manufacturing, R&D for its applications development and works closely with customers to help them succeed in bringing innovative products to their customers by giving customers the ability to develop innovative end-use products, providing value preposition of customers. Our exceptionally super quality EPS, which is the main component of Thermocol industries, is utilize as raw material for packaging materials like thermocol sheets, EPS block thermocol, pipe section thermocol as well as in construction industries for insulation and sustainable constructions and other miscellaneous uses like infrastructure industries.

Rattan Styrenics Pvt. Ltd. has dynamic, visionary business that is focused on a sustainable future. To further expedite our business processes from procurement of basic inputs to final delivery; infrastructure has been divided into specialized units. These units undertake only specific parts of the methodology, specifically, manufacturing, warehousing and packaging, a high-tech quality analyzing laboratory and finally research and development facility. Company is managed by a team of professionals who have been responsibly recruited in adherence to organizational objectives and targets. Management continuously focuses on improving business practices for making the business on win-win for the all the stake holders.

Our Products

EPS (Expandable Polystyrene) is a rigid cellular form of polystyrene. It is used as a primary raw material for manufacturing of Thermo Cole products for various applications such as thermal insulation of buildings, cold storage, industrial refrigeration & air conditioning and for thermal insulation in transport. The Main Product that is manufactured in the Company is EPS Expandable Polystyrene. It is available in different grades as follows:

Product Grades

|

Grades SE |

Grade Normal |

Bead Size Range (mm) |

|

EPS 3400 SE |

EPS 3400 |

0.3 to

0.4 mm |

|

EPS 4700 SE |

EPS 4700 |

0.4 to

0.7 mm |

|

EPS 7100 SE |

EPS 7100 |

0.7 to

1.0 mm |

|

EPS 9100 SE |

EPS 9100 |

1.0 to

1.18 mm |

|

EPS 8100 SE |

EPS 8100 |

0.7 to

1.18 mm |

|

EPS 1218 SE |

EPS 1218 |

1.18 to

1.80 mm |

|

EPS 1820 SE |

EPS 1820 |

1.8 to

2.0 mm |

|

EPS 2025 SE |

EPS 2025 |

2.0 to

2.5 mm |

|

EPS JUMBO SE |

EPS JUMBO |

>2.0 mm |

All our products are RoHS compliance.

Quality Output

Our objective is to maintain the excellence of our offered products. The expansive client base owned by us speaks volume about the perfection of our product ranges. Right from the stage of the procurement of raw materials till the final dispatch, our highly experienced team closely monitors our entire range of production to ensure its flawlessness. We assure quality of all our products we deliver all the time.

Customer Satisfaction

This is of utmost importance to us. We always go that extra mile to ensure the customers fulfillment. We build long lasting relationships with our customers. We ensure our clients that our products meet the international quality standards. In addition to this, we believe in making healthy relationship with clients to attain complete customer satisfaction.

Safety, Sustainability And Recyclability

We at Rattan Styrenics Pvt. Ltd. make every effort to ensure sustainable development through optimum use of resources and minimization of waste, by addressing the environmental impact of our relevant actions, product and services, by means of good standards and practiced Environmental Management System, with the complete participation of all our people.

Sustainability benefits of EPS are achieved by practicing many steps like during the EPS manufacturing, ozone-layer depleting agents like CFCs and HCFs are not used. CO2 emissions are reduced as EPS is very effective thermal insulation material which aids energy savings. It is inert and non toxic.

EPS is 100% recyclable. It is formulated from organic materials like carbon, hydrogen and oxygen and does not contain harmful chemicals. It can be easily recycled at any steps of its life cycle. EPS material can be reprocessed using various processes like granulation, blending and can be molded into new packaging products or durable goods.

Back to top